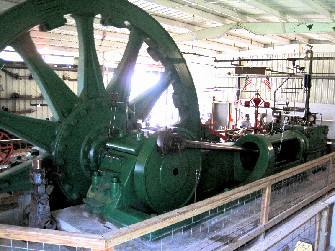

The Cooper Corliss Engine

The Cooper Corliss engine served The Matthiesen-Hegeler Zinc Company of Lasalle, Illinois from 1914 to 1965. One of six large engines, it powered a rolling mill and a line shaft that powered other equipment.

In 1981, Fred and Cynthia Carus of Lasalle, Illinois donated the engine to the Stephenson County Antique Engine Club. The club dismantled and moved the engine to Freeport. All labor and trucking were donated. Parts were stored until 1988 when the club acquired the former Stephenson County Nursing Home building, which now houses the museum.

In the yard behind the museum, a foundation was made for the 130-ton engine. Seven vertical holes 25 feet deep by two feet in diameter were drilled in the ground and filled with reinforced concrete to support a base containing nearly 100 yards of concrete and 4000 feet of 1-inch diameter steel reinforcement bars. The total cost was $16,000.

In 1989, the engine was then assembled by club volunteers. The 25-foot, 4-inch flywheel consistes of twelve 5-ton sections connected by 24 bolts, three inches in diameter, and 96 dog-bone shaped keys 2.5 inches square by thirty inches long. It is supported by a 25-ton crankshaft. Assembly of the engine required 12 hours.

In 1990, a 60 by 60 foot metal building was built over the engine at a cost of $30,000.

In 1991, the club located and purchased a used gas-fired boiler and installed it in the building with the engine. The engine was test run on July 13, 1991 at six rotations per minute. It is capable of 45 RPM.

In 1992 the engine was painted. This required 16 gallons of paint.

The engine is the largest flywheel steam engine within 500 miles of Freeport. The flywheel weighs 60 tons and stores a quarter million foot pounds of torque.

There is no admission to see the Cooper Engine. Donations are appreciated.

Corliss Valve Gear

Learn more about Corliss engines.